Mechanical-technological testing

What is meant by mechanical-technological tests?

In mechanical-technological test procedures, the behaviour of materials under certain mechanical stresses is examined. In addition to tests in the laboratory with standardised testing machines and test specimens, we also carry out operational tests with original components and systems as well as material tests using mechanical-electrical measuring sensors. The mechanical-technological tests in our laboratory can be divided into three main groups:

- Strength tests: In the course of strength testing, strength parameters (e.g. yield point, yield strength, tensile strength) and deformation properties (e.g. elongation at break, constriction at break) are determined. Depending on the test method, the material is subjected to various stresses (e.g. tension, compression, bending, shear, torsion) under specific time sequences (e.g. rapid, constant, abrupt, oscillating). The material characteristics are determined on test specimens with defined or standardised dimensions and under specified test conditions.

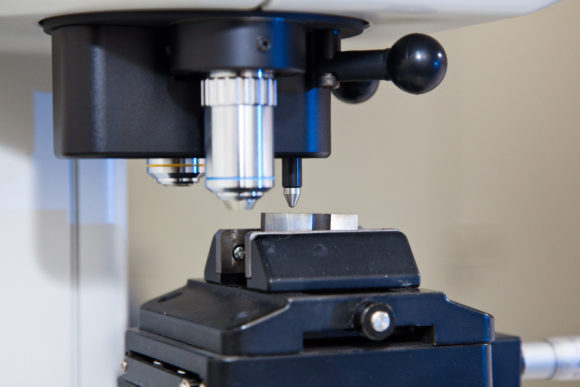

- Hardness testing: In hardness testing, the resistance of a material surface to plastic deformation by a standardised indenter is determined by precisely measuring its permanent indentation in the material surface. Depending on the test method, the indentation resistance is determined as the ratio of the test force to the surface of the indentation (Brinell hardness, Vickers hardness).

- Technological tests: Technological test methods are used to examine materials and components with regard to their manufacture, processing and further processing. The results are usually process-dependent, so that an exact specification of the test method, test object and test conditions is required. In our materials laboratory, we carry out tests in connection with joining processes (e.g. welded joints, soldered joints, adhesive joints) and tests of product forms (e.g. cast materials, forged parts, rolled products, deep-drawn sheets).

Range of services of our materials testing laboratory

Our materials laboratory has testing machines and equipment to carry out strength, hardness and technological tests in accordance with standards. The following table characterises the measuring and testing ranges.

| Measured variable | Measuring and testing range |

|---|---|

| Tensile / compressive force | 0.05 to 400 kN |

| Notched bar impact work | up to 150 J at -40°C to room temperature |

| Brinell hardness | 22.3 to 600 HBW (HBW 10/3000; HBW 5/250; HBW 5/62.5; HBW 2.5/187.5; HBW 2.5/62.5) |

| Vickers hardness | 10 to 3000 HV (HV 0.005; HV 0.01; HV 0.02; HV 0.05; HV 0.1; HV 0.2; HV 0.3; HV 0.5; HV 1; HV 5; HV 10; HV 30) |

Test lexicon

In the following table you will find some abbreviations for standardised designations.

| Abbreviation | Meaning |

| Rm | Tensile test: Tensile strength |

| Rp0,2 | Tensile test: Yield strength at 0.2 % plastic extensometer strain |

| ReH | Tensile test: upper yield strength |

| A | Tensile test: Elongation at break |

| Z | Tensile test: fracture constriction |

| KV | Notched bar impact test according to Charpy: consumed impact energy of a specimen with V-notch |

| KU | Notched bar impact test according to Charpy: consumed impact energy of a specimen with U-notch |

| HV | Hardness test: Vickers hardness |

| HBW | Hardness test: Brinell hardness |

| H MM HRC | Mobile hardness testing: by means of mechanical indentation depth measurement |

| CHD | Technological test: case hardening depth |

| Nht | Technological test: Nitriding hardness depth |

| DS | Technological test: hardening depth |

What are the advantages of mechanical-technological testing?

With mechanical-technological tests you can analyse the properties, quality and safety of your material or component. Use our tests to assess the functional and economic application of your product in the areas of manufacturing, further processing and process monitoring!

Are you in need of mechanical-technological testing?

We would gladly support you. Contact us for testing.