Protection type testing

What is IP protection type testing?

The abbreviation IP stands for International Protection. IP protection class tests show how protected the installed components of your products are by a housing from various environmental influences such as dust or water. Furthermore, IP tests can also determine the protection against contact and foreign bodies. In our protection type laboratory, we have a wide range of modern equipment to test all common degrees of protection for enclosures, electric motors and automotive parts. In addition, we also offer tests for the military sector and civil aviation.

What do the code numbers mean?

The first code number describes the degree of protection against access to dangerous parts and against solid foreign bodies. Various probes are used to check the access protection. These are intended, for example, to simulate access to dangerous parts with a finger or tools. Furthermore, the first code number describes the protection against solid foreign bodies such as dust. The higher the first code number, the more protection your enclosure offers against unwanted environmental influences.

The second code number declares the protection of an enclosure against water. Here, different water quantities and pressure strengths are used. These simulate different conditions, such as rain, water jets, diving or cleaning an enclosure with a steam jet cleaning device. For the degree of protection against water, the code numbers are divided into groups. For example, the code number 6 includes all low code numbers, which is why these do not have to be tested separately. The second group, with code numbers 7 and 8, describes the degree of protection an enclosure has against temporary or permanent immersion in water. The last group of water indicates the protection of an enclosure against a high-pressure cleaning test with high temperatures.

IP code breakdown

Protection level example: IP 6 5

| IP | Code letters (International Protection) |

| 6 | First code number (digits 0 to 6) |

| 5 | Second code number (digits 0 to 9 or 9K) |

Definition of the ratios

| First Code number | Brief description | Definition |

|---|---|---|

| 0 | No protection | - |

| 1 | Protection against solid foreign bodies Ø 50 mm and larger | The probe Ø 50 mm must not penetrate completely into the housing. |

| 2 | Protection against solid foreign bodies Ø 12.5 mm and larger | The probe Ø 12.5 mm must not penetrate completely into the housing. |

| 3 | Protection against solid foreign objects Ø 2.5 mm and larger | The Ø 2.5 mm probe must not penetrate the housing at all. |

| 4 | Protection against solid foreign objects Ø 1.0 mm and larger | The Ø 1.0 mm probe must not penetrate the housing at all. |

| 5 (K) | Dust-protected | The penetration of dust is not completely prevented, but the proper function and safety of the unit must not be impaired. |

| 6 (K) | Dust-tight | Dust must not penetrate the housing. |

| Second Code number | Brief description | Definition |

|---|---|---|

| 0 | No protection | - |

| 1 | Protection against dripping water | Vertically falling drops shall have no harmful effect. |

| 2 | Protection against dripping water with a 15° enclosure slope | Drops falling vertically shall have no harmful effect if the enclosure is tilted by 15°. |

| 3 | Protection against spray water | Water sprayed from an angle of up to 60° shall have no harmful effect. |

| 4 (K) | Protection against splashing water | Water sprayed on the enclosure from any direction shall have no harmful effect. |

| 5 | Protection against water jets | Water jets directed against the enclosure from any direction shall have no harmful effect. |

| 6 (K) | Protection against strong jets of water | Strong jets of water directed against the enclosure from any direction shall have no harmful effect. |

| 7 | Protection against temporary immersion | Water shall not penetrate the enclosure at a standardised depth and duration in such quantity that it has a harmful effect. |

| 8 | Protection against permanent submersion | Water shall not penetrate the enclosure at a continuous test in such quantity that it has a harmful effect (the test conditions shall be more severe than for code number 7). |

| 9 (K) | Protection against high pressure and high water temperatures | Water directed against the enclosure from all directions at high pressure and temperature shall have no harmful effect. |

Testing for the aviation and military sectors

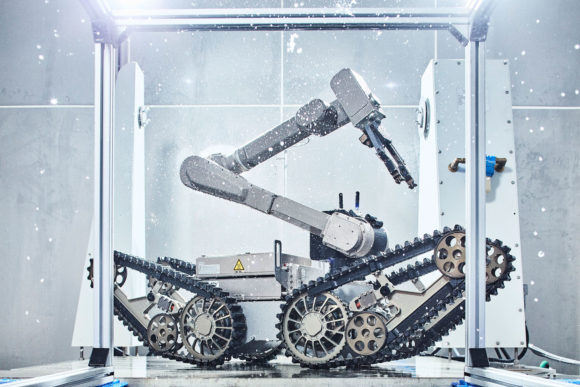

In our protection type laboratory, we also have equipment with which we can test the highest requirements for enclosures. In our laboratory, for example, the abrasive effect of highly swirling dust on your components and enclosures is tested. The combination of water and wind can also be simulated in our laboratory.

What are the advantages of IP protection class tests?

Thanks to the know-how of our engineers and our modern facilities, we can test all common degrees of protection, such as IP65. Special tests in the area of protection classes are also possible with us. Our facilities with a volume of more than 50 m³ and a floor load of up to three tonnes ensure that we can detect and eliminate any weak points on test samples with a height of up to three metres. This early control can reduce production costs and prevent image damage due to product liability. Additionally, , our accredited test reports also give you an advantage over your competitors.

Are you in need of protection type testing?

We would gladly support you. Contact us for testing.