Temperature testing

What is meant by temperature tests?

Temperature tests are divided into cold tests, heat tests, temperature change tests and temperature shock tests. Temperature tests allow us to simulate aging processes under laboratory conditions and to check whether your product is suitable for the place of use and functions properly.

Range of services of our temperature laboratory

Our temperature laboratory has a wide range of modern equipment for temperature tests open to the industry in the range from -70 °C to 300 °C. Due to the wide range of temperatures, our experienced engineers can simulate any place of use for your product worldwide. With a temperature change test at up to 8 K/min, we can also simulate temperature sequences such as the day-night change.

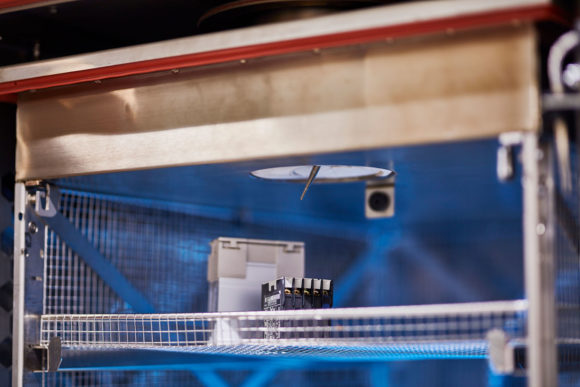

Sudden temperature shocks, such as driving a motor vehicle through a puddle or using a mobile phone in winter, expose your products and materials to high thermal stresses. We can simulate these stresses using various methods in our thermal shock chambers. Our testing facilities, which are open to all sectors, enable tests in the shock variants air-air, air-water and surge water.

The temperature laboratory has a large number of testing and measuring devices. This enables us to monitor and record a wide range of parameters of your products during testing.

Test lexicon

In the following table you will find some abbreviations for standardised test procedures.

| Abbrevation | Meaning |

|---|---|

| Ab | Cold for non heat-dissipating specimens with gradual change of temperature |

| Ad | Cold for heat-dissipating specimens with gradual change of temperature |

| Ae | Cold test for permanently electrically supplied and heat-dissipating specimens |

| Bb | Dry heat for non heat-dissipating specimens with gradual change of temperature |

| Bd | Dry heat for heat-dissipating specimens with gradual change of temperature |

| Be | Dry heat for for permanently electrically supplied and heat-dissipating specimens with gradual change of temperature |

| Na | Rapid change of temperature with prescribed time of transition |

| Nb | Change of temperature with specified rate of change |

| Nc | Rapid change of temperature, two-bath method |

What are the advantages of temperature testing?

Temperature testing allows you to identify and eliminate potential weaknesses early on in the product development phase. This lowers your production costs and reduces the risk of image-damaging product liability. Furthermore, our accredited test reports ensure additional confidence in your brand and give you a competitive advantage over your competitors.

Are you in need of temperature testing?

We would gladly support you. Contact us for testing.