Testing of fasteners

What is meant by fasteners and their testing?

Connections are divided into detachable connections (e.g. screw connections) and non-detachable connections (e.g. welded connections). A screw connection is a detachable connection of two or more parts, which is connected by one or more threaded rods (e.g. screws or bolts) with an external thread and components with an internal thread (usually nuts). When the screw or nut is turned, sliding occurs in the thread between the flanks of the thread and longitudinal movement occurs, achieving a form fit between the components.

Tests on fasteners:

- Non-destructive testing: testing for e.g. cracks in the thread by means of surface crack testing

- Mechanical tests: Testing of material conformity to standards or drawing specifications with regard to hardness, tensile strength and yield point.

- Chemical analyses: Testing of material conformity with standards with regard to the material of the fastener and its coating

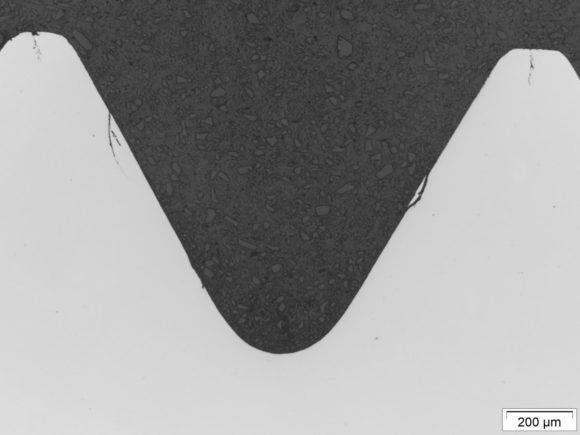

- Metallographic examinations: Testing of material conformity with standards with regard to microstructure and coating as well as examination of e.g. thread irregularities such as overrolling or head folds.

Range of services of our materials testing laboratory

Our materials laboratory has the testing instruments and equipment to carry out the various tests in the field of materials testing.

Test lexicon

In the following table, you will find some abbreviations for named designations.

| Term | Meaning |

| Screw | Fastener consisting of a head and a threaded rod (cylindrical body with external thread) needed to interact with a nut and fasten two parts with through holes. This type of connection is called a bolted connection. When the nut is unscrewed from the bolt, the two parts can be separated so that the bolt connection is a detachable connection. |

| Nut | With internally threaded holes, the shape is generally flat hexagonal, cylindrical or flat cylindrical |

| Bolt | A type of cap without a head, threaded only at both ends. When connecting, one end must be screwed into the part with the female threaded hole and the other end through the part with the through hole. The nut is then screwed to the bolt . This type of connection is called a bolt connection, it is a detachable connection. |

What are the advantages of examining fasteners?

By regularly inspecting fasteners, you can prevent component failures and thus damage that is usually significantly higher than the failure of the fastener alone. Because when a connection fails, the entire component often fails as well. Take advantage of our testing of fasteners - and make your component fail-safe!

Are you in need of a testing of fasteners?

We would gladly support you. Contact us for testing.